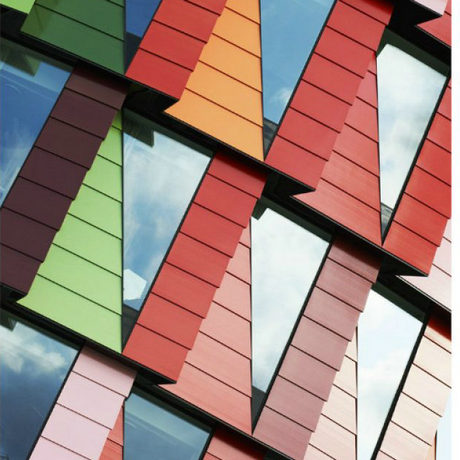

PVDF mainly refers to the coating of vinylidene fluoride homopolymer or copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer. The chemical structure of the fluoric acid base material is bonded by a fluorine/carbon bond. The stability and firmness of this chemical structure make the physical properties of fluorocarbon coatings different from ordinary coatings. In addition to its abrasion resistance and impact resistance in terms of mechanical properties, it has excellent performance, especially in harsh climates and environments showing long-term fading resistance and UV resistance. After roasting at high temperature to form a film, the molecular structure of the coating is tight, and it has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon and nano-fluorocarbon coatings according to the surface film-forming structure. In 1965, the United States Pennwalt Chemical Company first applied fluorocarbon coatings to meet the indoor and outdoor aluminum coating of high-end buildings. A wide range of color choices, American solemn appearance, and durability have added brilliance to many magnificent curtain wall buildings around the world. The coating manufacturer's guarantee for the service life of the coating starts from 10 years and 15 years and can be guaranteed to be guaranteed for more than 20 years. American research institutions have tested and compared fluorocarbon coatings, super coatings, and general coatings. The coated samples were exposed to hot sunlight in Florida and exposed to the harsh environment of humid and salty air12 In 2001, it was proved that the stability and durability of fluorocarbon coatings are 30 and 80 percentage points higher than those of the other two coatings. Fluorocarbon coatings are guaranteed to be used in various harsh environments. It is particularly suitable for the decoration and display of indoor and outdoor decoration in public places, commercial chains, exhibition advertisements, etc.

-

Building

-

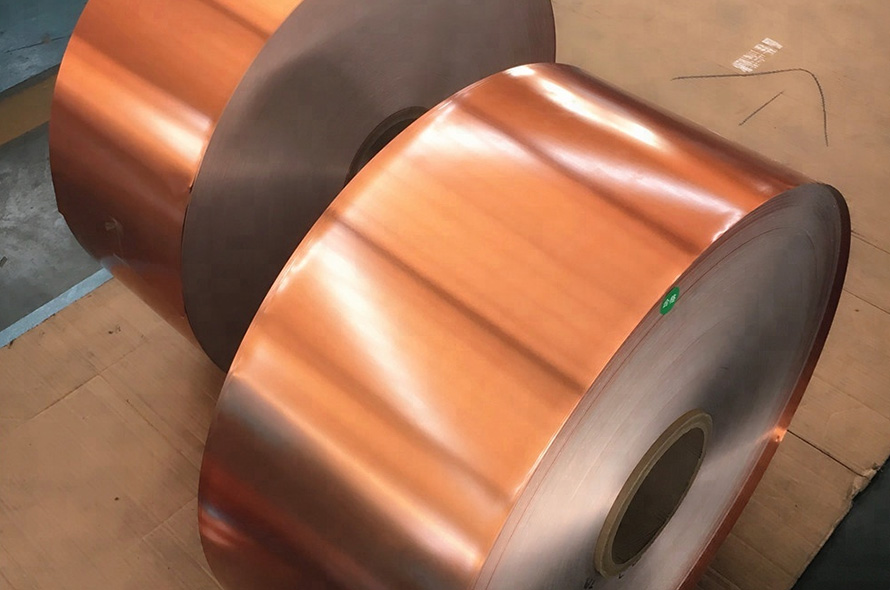

Veneer processing

-

Wall panel