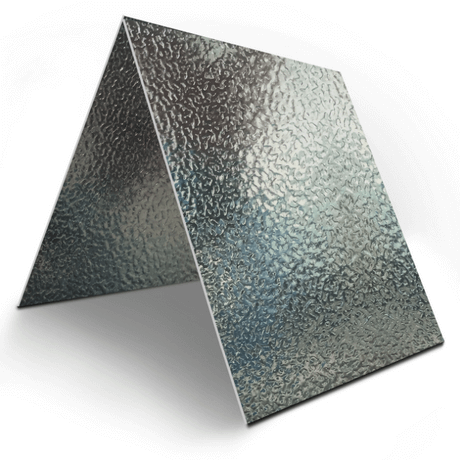

4x8Aluminum Sheet

2025-08-23

The following provides a detailed introduction to the characteristics and commonly used alloys of 4x8 aluminum plates.

---

I. Main features of 4x8 aluminum plates

1. Standard size, easy to purchase and process

· This is a globally applicable standard size with ample inventory and numerous suppliers. Purchasing is very convenient as there is no need for customization and waiting. The prices are also relatively transparent.

· During design and cutting layout, the standard size ensures high material utilization and effectively reduces waste.

2. Relatively convenient for transportation and handling

· Compared to larger-sized aluminum plates, the 4x8 size is suitable for common logistics trucks for transportation and also convenient for manual or mechanical handling (such as using suction machine) in the factory workshop.

3. Extremely wide range of applications

· This size perfectly matches the standard requirements of many fields, such as the size of building templates, ceiling modules, and paneling for machine shells.

4. Excellent comprehensive performance

· Based on different alloys and states, it can provide various performances ranging from high plasticity to high strength, meeting different needs from deep drawing to structural support.

---

II. Common 4x8 Aluminum Plate Alloys and Their Characteristics and Applications

Which alloy to choose depends entirely on your application scenario and the requirements for strength, hardness, corrosion resistance, weldability and machinability.

Here are several of the most commonly used types of aluminum alloys:

1. Series 1 aluminum alloy (such as 1060, 1100)

· Feature: The purity is over 99%, it is a typical industrial pure aluminum.

· Advantage: Excellent corrosion resistance, good thermal and electrical conductivity, extremely high plasticity, easy to be stretched and formed by stamping.

· Disadvantage: The lowest strength, relatively soft.

· Main applications:

· Inner lining of chemical storage tanks (corrosion resistant)

· Signboards, kitchen utensils

· Deep stamping products (parts requiring significant deformation)

· Various low-demanding reflectors, heat exchanger components.

2. 3-series aluminum alloy (with 3003 as the representative)

· Feature: It is one of the most widely used anti-rust aluminum alloys. It is made by adding approximately 1.2% manganese (Mn) to pure aluminum.

· Advantage: Its strength is about 20% higher than that of the 1 series, and it has excellent corrosion resistance and excellent formability. It is a cost-effective general-purpose alloy.

· Disadvantage: It cannot be strengthened through heat treatment.

· Main applications:

· Kitchen and bathroom ceilings, wall partitions

· Refrigerators, air conditioning ventilation ducts

· Sheet metal chassis, cabinets, filing cabinets

· Vehicle interior panels, fuel tanks

3. 5-series aluminum alloy (with 5052 as the representative)

· Characteristics: It is a medium-high strength anti-rust aluminum alloy, with magnesium (Mg) as the main alloy element.

· Advantages: Excellent corrosion resistance, especially in marine climates (resistant to seawater corrosion), high fatigue strength, good formability and weldability. The strength is significantly higher than that of the 3 series.

· Disadvantages: Not suitable for use in high-temperature environments.

· Main applications:

· Sheet metal parts for ships, cars, and aircraft

· Fuel tanks, oil pipes

· Decorative panels for buildings, pressure vessels

· Enclosures for electronic products requiring high strength.

4. 6 Series aluminum alloy (with 6061 as the representative)

· Feature: It is the most classic heat-treated strengthened alloy, containing magnesium and silicon. It can achieve high strength through heat treatments such as "T6".

· Advantage: It has excellent comprehensive performance, with high strength (close to low-carbon steel), good corrosion resistance, excellent machining properties (such as CNC) and welding properties. It is called the "universal aluminum".

· Disadvantage: Its forming plasticity is not as good as that of 3 series and 5 series, and it is not suitable for complex forming processes such as deep drawing.

· Main applications:

· High-strength mechanical structural components, frames, bases

· Automotive wheels, bicycle frames

· Precision instrument structural components

· Mold plates, stands

Previous Page:

Share:

.jpg)

.jpg)