Aluminum Strips - A Complete Guide to Applications

Industry Insight: The Evolution of Precision Aluminum Strips - A Complete Guide to Aluminum Strip Applications

– In the global trend towards manufacturing precision and lightweighting, precision aluminum strips, as a key foundational material, are garnering increasing attention for their technological advancements and application selection. A professional aluminum strip supplier does not merely provide products but is committed to delivering comprehensive material solutions.

Precision Aluminum Strips: Definition & Key Parameters

Precision aluminum strips refer to aluminum or aluminum alloy strips produced through processes like cold rolling and foil rolling, characterized by high accuracy in thickness, width, and flatness. Key parameters include:

-

Alloy & Temper: Common alloys include the 1xxx series like 1050, 1060 (excellent conductivity), the 3xxx series like 3003, 3005 (good corrosion resistance and formability), and higher-strength alloys like 5052, 6061 (structural strength). Temper (e.g., O-annealed, H-work hardened) defines the strip's softness/hardness and formability.

-

Thickness: Typically ranges from 0.05mm to 2.0mm, customizable based on application needs. Ultra-thin strips (<0.1mm) are often used in electronic components and capacitors.

-

Width: Standard widths range from a few millimeters(e.e.,5mm) to several hundred millimeters, offering high customizability. Widths in the tens of millimeters(e.g.,20mm 36mm 50mm) are particularly common for applications like battery

tabs and electronic component leads. -

Precision Aluminum Strip: The Unsung Hero in Modern Manufacturing

The precision aluminum strip, a fundamental and vital metallic material, is deeply integrated into every facet of modern industry, thanks to its excellent electrical and thermal conductivity, light weight, high strength, and superior formability. Through advanced cold rolling and heat treatment processes, we supply aluminum strips in various alloys and tempers (e.g., O, H), with thickness precisely controlled from a fraction of a millimeter to several millimeters, and widths customizable to meet the exact requirements of diverse applications.

Key Application Fields:

-

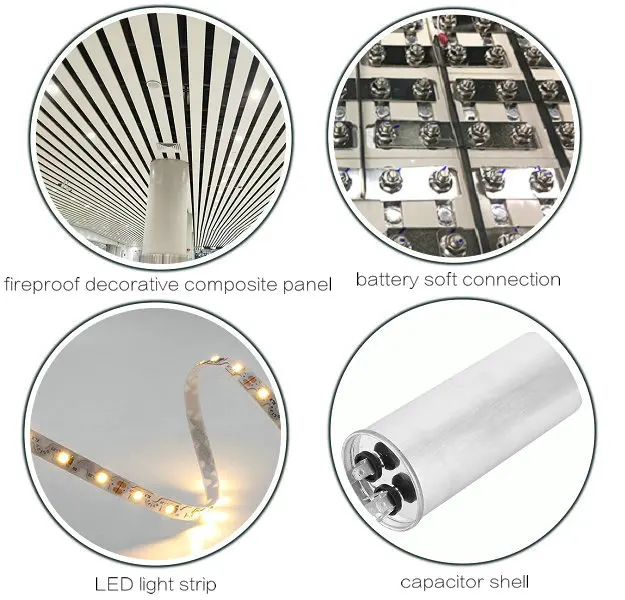

New Energy & Electrical Engineering: Aluminum strips are the ideal choice for manufacturing lithium battery tabs, capacitor casings, and electrical busbars. Their high conductivity and stable chemical properties ensure the efficiency and safety of energy storage and transmission.

-

Electronics & Microelectronics: In precision components such as IC lead frames, EMI shielding covers for electronic components, and sensor bases, aluminum strips provide excellent electromagnetic shielding and reliable mechanical support.

-

With its versatile design adaptability and reliable performance, the precision aluminum strip continues to provide a solid material foundation for innovation and advancement across countless industries.

-

Packaging & Consumer Goods: From blister packaging for food and pharmaceuticals, pull-tab lids for cans, to anti-counterfeit tags and decorative trims for premium goods, aluminum strips ensure packaging integrity, aesthetics, and hygiene.

-

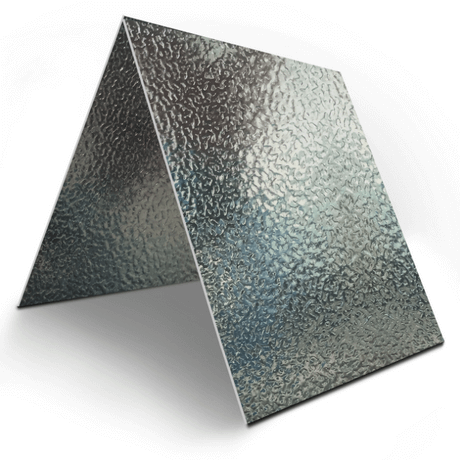

Industrial & Construction: In industrial sectors, aluminum strips are used to create heat sinks and heat exchanger fins. In construction, they serve as high-quality substrates for decorative trims, moldings, and sealing systems.

.jpg)

.jpg)