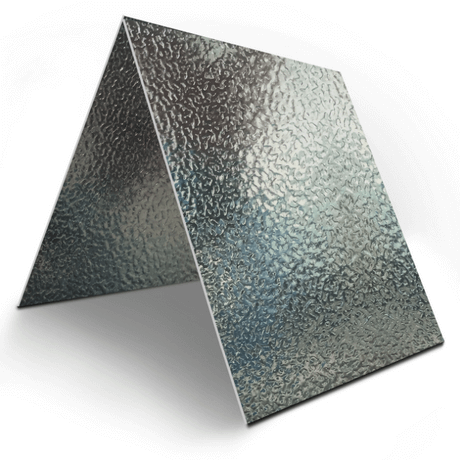

8011 Alloy Aluminum Foil

Aluminum foil, known for being lightweight, barrier-resistant, and corrosion-resistant, permeates every aspect of our lives.From baking liners and food wraps in kitchens to a wide array of food containers in supermarkets, the core material is often the high-performance 8011 Aluminum Alloy.This article provides an in-depth look at 8011 alloy foil, from its material properties to common specifications for both coils and finished containers.

8011 alloy is an Al-Fe-Si series alloy renowned for its unique composition, offering these outstanding advantages:

-

Excellent Deep Drawing Performance: Resists cracking when formed into various container shapes, ensuring good formability.

-

Good Corrosion Resistance: Effectively withstands acids and alkalis in food, extending shelf life.

-

High Barrier Properties: Completely blocks light, oxygen, and moisture, protecting the flTheavor and quality of contents.

-

Compliant with Food Contact Standards: Safe and non-toxic, making it ideal for food packaging.

-

Smooth Surface: Results in aesthetically pleasing containers that are easy for printing and coating.

Thanks to these properties, 8011 alloy has become the preferred material for producing household foil rolls, food-grade aluminum foil containers, and industrial foil.

Foil coils are the base material for further processing. Their specifications are primarily defined by Thickness and Width.

.png)

Aluminum foil rolls, as a packaging material, possess a number of superior features. First of all, it is lightweight and flexible, making it convenient for packaging and carrying. Secondly, aluminum foil rolls have excellent anti-oxidation and barrier properties, which can effectively isolate external factors such as air, moisture, light and odors, maintaining the freshness and quality of the packaged items. In addition, aluminum foil rolls have excellent thermal conductivity and heat insulation properties, and can be used for special packaging requirements such as food preservation and pharmaceutical refrigeration. The manufacturing process of aluminum foil coils involves multiple steps. Firstly, after the smelting of aluminum ingots and alloy adjustment, the aluminum raw materials are melted and cast into aluminum plates. Then, the aluminum plate is processed into thinner aluminum foil coils through the rolling process. During the rolling process, surface treatments such as coating, printing and lamination can also be carried out on the aluminum foil coils to enhance their functionality and aesthetic appeal. Finally, after cutting and winding, the aluminium foil is made into rolls for convenient packaging and use.

Whether as raw material in the form of foil coils or as the final product in consumers' hands, the 8011 alloy is the cornerstone of their superior performance. Selecting the appropriate thickness and width is crucial for ensuring production efficiency and product quality. As a professional aluminum supplier, we provide complete solutions from 8011 alloy aluminum foil coils to customized aluminum foil containers. If you have any questions or requirements, please feel free to contact us for professional technical support and quotations.

.jpg)

.jpg)